Cross Connection Information

Any actual or potential physical connection between a public water system or the consumer’s water system and any source of non-potable liquid, solid, or gas that could contaminate the potable water supply by backflow. A garden hose left in a swimming pool is an example of this. Cross-connection control helps to manage and protect the public or consumer’s clean water supply.

For details regarding cross connection regulations and our Cross Connection Control Program guidelines, click here.

Picture that garden hose in the swimming pool. If the pool water is sucked back into the hose towards the house there is potential to contaminate the clean water supply. This is known as backsiphonage. Backpressure is another way backflow can occur. This is when pressure (caused by a pump, elevated tank or piping, boiler, or other means) on the consumer’s side of the service connection that is greater than the pressure provided by the public water system and which may cause backflow. A backflow prevention device is essential to ensure water quality and protect public health.

Examples of cross-connections systems:

· Fire sprinkler systems

*residential fire sprinkler info

· Irrigation or in-ground sprinkler systems

· Swimming pools

· All commercial buildings

· Boilers

· Soda Dispensers

Customers are responsible for all costs associated with the installation, testing, maintenance, and repair of backflow prevention assemblies.

All backflow incidents are not the same. Depending on the non-potable source, cross-connections are classified as low, high or severe health hazard and will require a qualified person to determine the appropriate device needed. See some examples below:

Who can test and how often is a test needed?

A Backflow Assembly Tester (BAT) with a valid BAT certificate is required to test each assembly annually.

DCVA – Double Check Valve Assembly

Protection for lower hazards, such as landscape irrigation systems. The DCVA is the only assembly accepted by PL&WCo Cross Connection Control Program for irrigation systems.

RPBA – Reduced Pressure Backflow Assembly

Protection for high hazards, such as boilers, x-ray machines, soda dispensers, etc. The RPBA is the only assembly accepted by PL&WCo Cross Connection Control Program for commercial properties, auxiliary water supplies such as a private well or irrigation water taken from a lake or stream.

Installing your RPBA outside is a good idea and here’s why.

PVBA – Pressure Vacuum Breaker Assembly

Protection for lower hazards, such as irrigation systems. PVBA’s do not meet PL&WCo Cross Connection Control Program standards.

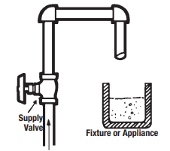

Air Gap

An Air Gap is a physical separation between the free-flowing discharge end of a potable water supply pipeline and the overflow rim of an open receiving vessel. Protection for high and Severe hazards, such as a chemical tank.

HBVB – Hose Bib Vacuum Breaker

Protection for house hose bibs. Note: Even if a HBVB is attached to the house, you should never lay a hose inside a hot tub or swimming pool.

Please see more detailed explanations and a definition of cross-connection terms here.

#1

A Pierce County Utility customer called stating the customer was taking a shower in their upstairs bathroom and lost all water. When the Utility responded they found that the Fire Department was on the scene at the neighbor’s home,

fighting a home fire. The fire department was using the hydrant. They pumped the water so fast they dropped the system pressure down below the legal 20 psi, and the neighboring house had all of its water sucked out!

#2

A Pierce County Utility, who does not chlorinate their water, was surprised when a customer called to complain about chlorine in their water. An inspection test of the water at the home, confirmed the presence of chlorine in the

residential water. It was discovered that a neighbor had been filling their pool with water and the pool had been heavily chlorinated. They had left the fill hose in the pool and still attached to the hose bib. A drop in water pressure had occurred in

the neighborhood and back-siphonage to the local water main had taken place.

#3

The management of a convenience store complained of a bad taste in the soda and coffee. A Pierce County Water Utility responded immediately. The carbonate was malfunctioning causing CO2 to enter the water lines. A Cross Connection Specialist

shut off the water and the store manager called their maintenance department. It is unknown how this backflow occurred. The manager of the store said the canister of CO2 was new. Upon inspection there was a CO2 leak, as the canister of CO2 was almost

empty causing a siphonage event. Since this event, they installed backflow devices in all their stores.

#4

A Pierce County Utility received a call from the management of a convenience store regarding a metallic taste in the soda machine. The RPBA had just been installed on the soda machine by a plumber. All water lines and the soda

machine were flushed until the taste was gone. After discussing the problem with the plumber, it was determined that a backflow incident had occurred when the RPBA was installed on the water line. The soda machine had been left on causing a backflow of

CO2 mixed with water to enter the soda machine, the water travelled from a copper line making this a high hazard. Fortunately, no one ingested any of this soda. The Utility is now aware that these soda machines and carbonator’s must be shut down while

being worked on.

#5

A Pierce County Utility received a call from a dental clinic stating that they were experiencing air in the water at the dental chairs. The dental clinic was required to have the premise isolation RPBA tested immediately while

the Utility CCS team inspected the dental clinic. The complexity of the dental clinics vacuum pump and air pump systems required the dental clinics contractor which maintains that system to come in immediately to troubleshoot those systems. The premise

isolation RPBA passed its test. It was identified by the contractor which maintains the vacuum and air systems that an electric control valve failed which pushed air into the water systems at the dental chairs. Additional in-premise protection was advised

to be installed. The backflow incident was contained within the dental clinic only.

#6

A Pierce County Utility received a call from a customer stating that the water tasted bad, but it was only bad from the kitchen faucet. The Utility CCS inspected the property and identified that the customer had a garden hose connected

to the hose bib located below the kitchen window. The hose bib was in the on position. At the end of the hose the customer had a timer to water their garden at night. During the daytime the sun was heating the garden hose which caused thermal expansion

of the water within the hose. Once the customer was instructed by the Utility CCS what they suspected was the cause of the bad tasting water, corrections were made by the customer. A follow-up call to the customer was made to verify if the removal of

the hose from the hose bib took care of the bad tasting water. The customer confirmed that it did. The suspected backflow incident appeared to be contained to the customer’s kitchen area of the house only.

#7

A Pierce County Utility received a call from a customer stating that they were going to repair a leak at their house. They asked for assistance from a Utility serviceman because they turned the water off at the Premise Isolation

RPBA after the meter, but it seemed like the valve was leaking by because they couldn’t bleed the pressure off. Upon arrival the Utility serviceman verified that the meter and RPBA were turned off. The customer then remembered that they use Utility water

to prime the irrigation pump, which pumps water out of the lake to irrigate their lawn. By the time the customer realized what they had done; lake water had been pumped throughout the customer’s house plumbing. The customer turned off the hose which was

connected from the house hose bib to a hose bib on the irrigation pump head. Disinfection and flushing of the customer’s home plumbing and a new test of the customers RPBA were required. If this property had not been identified in the past as having an

Auxiliary Water Supply the public water system would have been at risk. This is a great example as to why all properties should be inspected. If there wasn’t a cross connection identified last year at a property it doesn’t mean something has not changed

on the property since then.

Note: PL&W is required to enforce the cross-connection regulations as set forth by the Washington State Department of Health. Our requirements exceed the minimum regulations in some areas. Please refer to our cross-connection information here for further details or contact us with any questions.